General Introduction

Flux is a key component in modern soldering, determining the quality, reliability, and durability of solder joints. With the rise of DIY electronics, smart devices, and microcontroller projects, the need for a detailed look at current flux options has become essential.

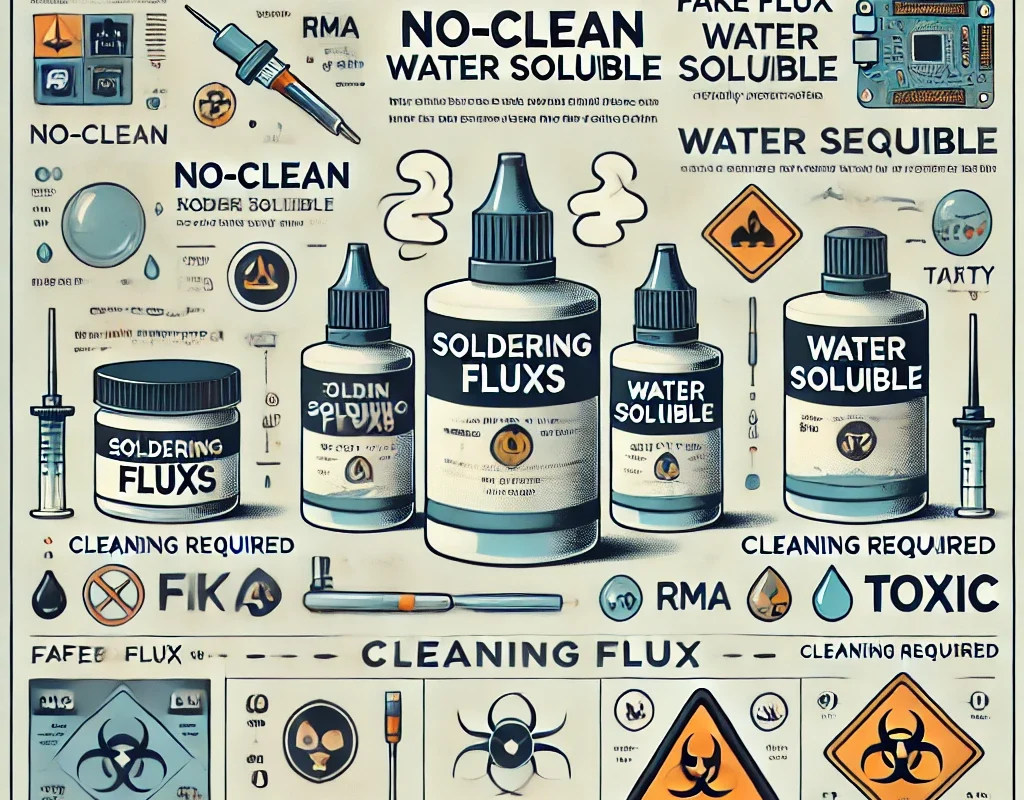

Types of Modern Fluxes

- No-Clean Flux

- Features: Does not require cleaning after soldering

- Pros: Convenient for quick, in-field, or temporary jobs

- Cons: Can leave a thin resin layer that may degrade over time and become resistive

- RMA (Rosin Mildly Activated)

- Base: Rosin with a mild activator

- Good for: Rework and repeated soldering cycles

- Cleaning: Recommended for high-reliability systems

- Water Soluble Flux

- Highly active, but residues are corrosive

- Requires warm water cleaning

- Best for: Production environments, not suitable for DIY or hobby work unless properly cleaned

Comparison of Popular Models

| Model | Type | Composition | Cleaning | Safety |

|---|---|---|---|---|

| Amtech NC-559 | No-Clean | Gel | Not required | Relatively safe |

| Kester 951 | No-Clean | Alcohol-based | Not required | Leaves no toxic residues |

| RELIFE RL-404 | RMA | Rosin + mild activators | Recommended | Safe after cleaning |

| Superior 30 | Water Soluble | Acidic base | Required | Unsafe if not properly cleaned |

Fake Fluxes: What to Watch For

The electronics market, especially online platforms, is full of counterfeit or low-quality fluxes. These are often:

- Labeled as “Amtech” but contain no real branding

- Sold in cheap packaging or unlabeled syringes

- Have a pungent, chemical smell or bubble violently when heated

Common Issues:

- Corrosion after just a few weeks

- Conductive residue that causes short circuits

- Toxic fumes, especially from unknown gel-type fluxes from unverified sellers

How to Avoid:

- Buy from authorized distributors or reputable electronics suppliers

- Check for batch numbers, proper labeling, and sealed packaging

- Prefer trusted brands: Amtech, Kester, ChipQuick, MG Chemicals

Recommendations and Best Practices

- For everyday DIY soldering with low risk: Use No-Clean (e.g., Amtech NC-559, Kester 951)

- For precision rework and high-load circuits: Use RMA-type fluxes and clean after use

- For mass production or fine-pitch work: Water-soluble fluxes with thorough cleaning are acceptable

- Avoid unknown brands or low-cost fakes — they can damage both hardware and your health

Always work in a well-ventilated area, use fume extraction, and wear protective gloves when handling fluxes.