📜 1. History of Breadboards

- 🔹 Origins:

- The term “breadboard” originally comes from the wooden boards used for cutting bread. Later, electronics enthusiasts adopted the term to describe a board used for prototyping circuits.

- In the early days of electronics, hobbyists would mount components on wooden boards or similar surfaces.

- 🔹 Evolution:

- In the 1970s, solderless breadboards were developed, allowing for quick, reusable circuit assembly without soldering.

- This innovation revolutionized prototyping by making it easier for engineers, students, and makers to experiment with circuit designs.

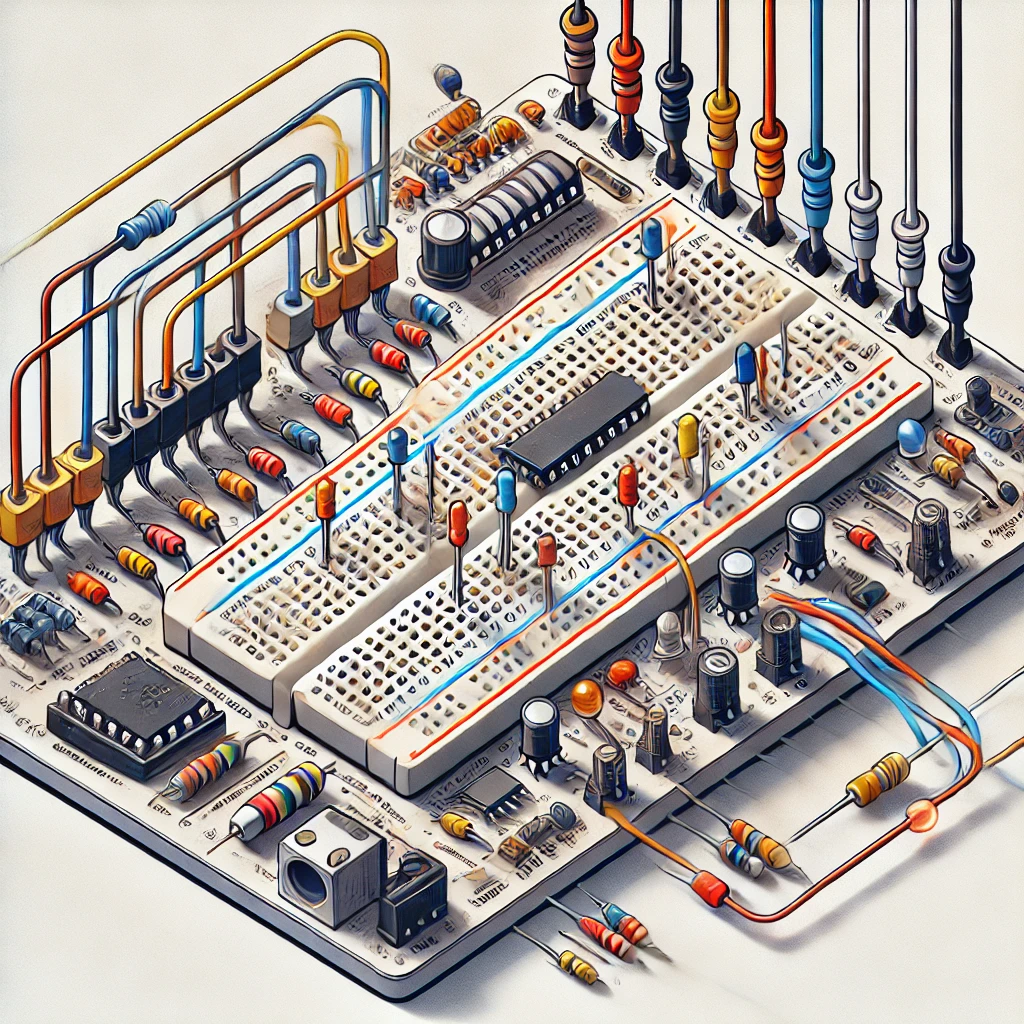

🔧 2. Applications of Breadboards

- 📚 Education:

- Widely used in classrooms and labs to teach electronics and circuit design.

- 🏠 DIY Projects:

- Perfect for prototyping home automation systems, robotics, and IoT devices.

- 💡 Prototyping:

- Essential for quickly testing and iterating circuit designs before creating a permanent PCB.

- 🔬 Research & Development:

- Used by professionals for preliminary experiments and proof-of-concept designs.

🔍 3. Comparison of Breadboard Types

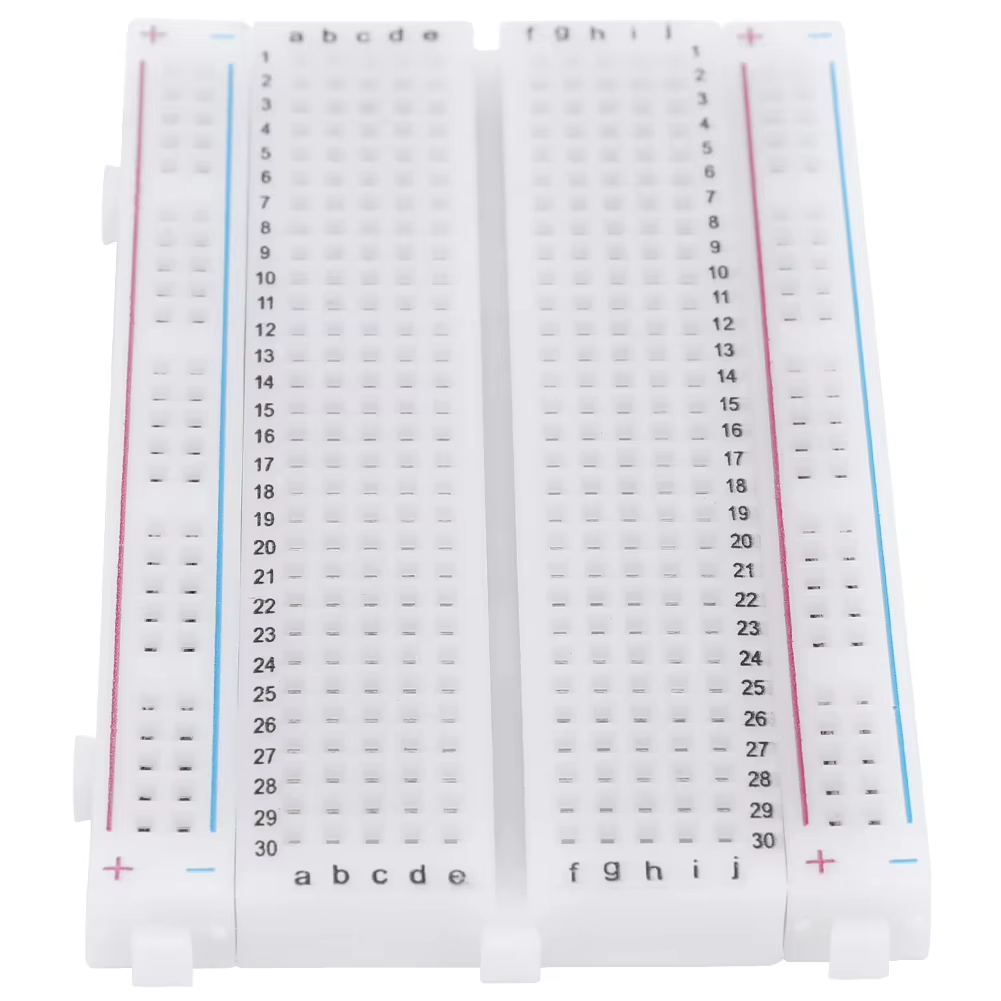

A. Solderless Breadboards

- Features:

- Reusable and no soldering required.

- Consist of a plastic grid with spring-loaded metal contacts.

- Available in various sizes (mini, full-size, power supply integrated, etc.).

- Pros:

- Easy to set up, modify, and reuse.

- Ideal for beginners and rapid prototyping.

- Cons:

- Limited current capacity; not suitable for high-power circuits.

- Connections may become unreliable over time with extensive use.

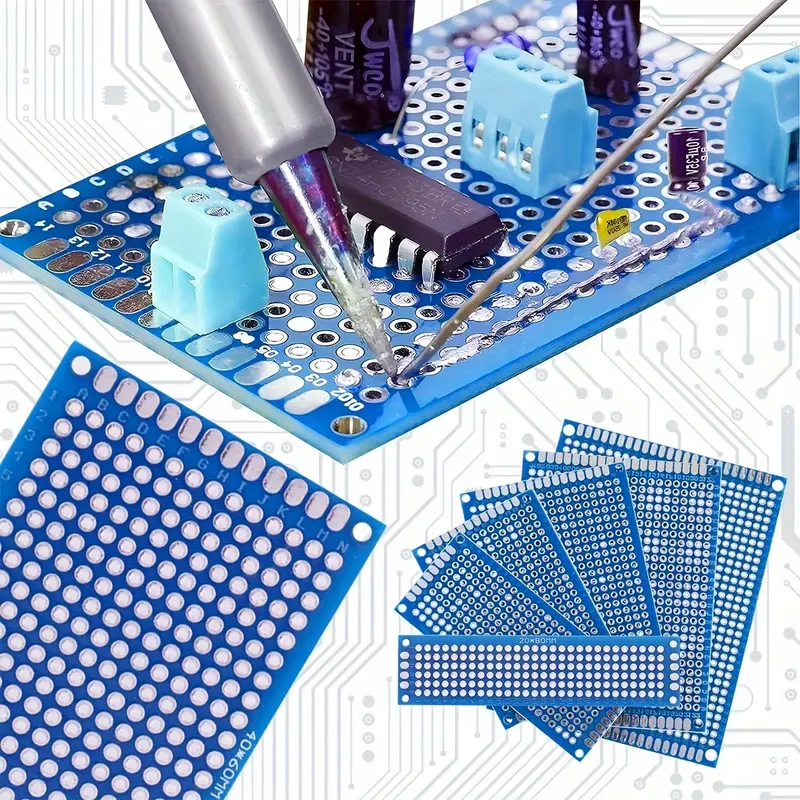

B. Soldered Protoboards (Perfboards/Stripboards)

- Features:

- Components are permanently soldered onto the board.

- Offers a more robust and durable connection.

- Pros:

- Better for long-term projects where stability is crucial.

- Provides improved electrical performance in some cases.

- Cons:

- Not reusable; modifications require desoldering.

- Assembly takes more time compared to solderless breadboards.

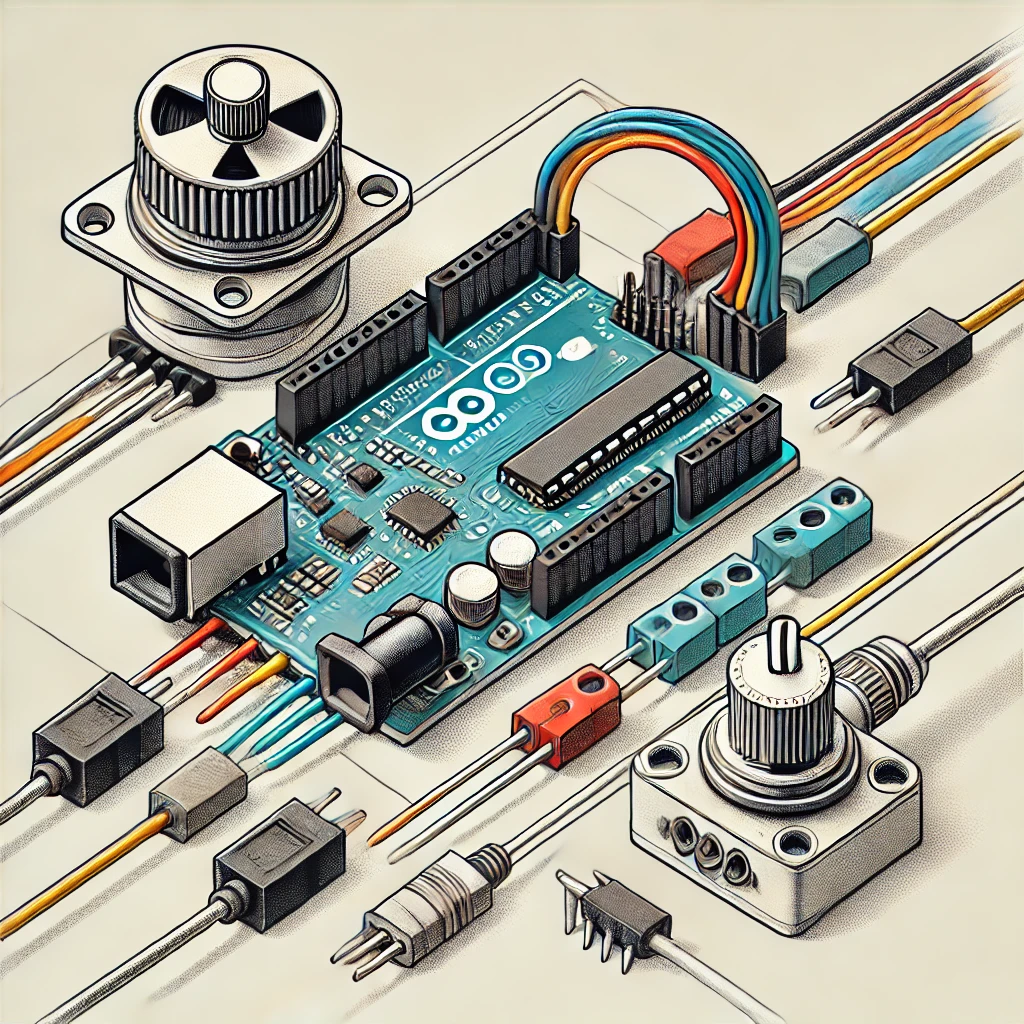

C. Custom Prototyping Boards

- Features:

- Tailor-made for specific projects, often with integrated power rails and connectors.

- Pros:

- Optimized for particular applications, bridging the gap between prototyping and final PCB design.

- Cons:

- Less flexible than standard solderless breadboards.

- Typically require soldering and more upfront planning.

🎯 Conclusion

Breadboards are indispensable in electronics due to their:

- Flexibility: Quickly reconfigure circuits for testing and learning.

- Accessibility: Perfect for beginners, educators, and hobbyists.

- Variety: Options range from solderless boards for rapid prototyping to permanent solutions like perfboards for stable, long-term projects.