Key Features:

- Type: DC gear motor.

- Voltage: Typically operates at 3V to 6V.

- Speed: These motors usually offer speeds ranging from 100 RPM to 200 RPM when running at 6V, though this can vary depending on the specific model and voltage.

- Torque: The gearbox reduces the speed but increases the torque, making them powerful enough to drive the wheels or tracks of small robots.

Construction:

- Gearbox: Attached to the motor is a reduction gearbox. The most common configurations are plastic gears, which help reduce the cost and are sufficiently robust for light-duty applications.

- Motor Shaft: The output shaft from the gearbox usually has a double-flat or cross-cut profile, which makes attaching wheels, gears, or other mechanisms easy without the need for additional couplings.

- Size: Compact and easy to mount in small projects. Dimensions can vary slightly but are generally small enough for use in miniature robotics.

Applications:

- Educational Robotics: Widely used in educational kits for schools and workshops to teach basic robotics and engineering concepts.

- DIY Projects: Ideal for DIY enthusiasts building simple robotic vehicles or mechanisms.

- Hobbyist Projects: Common in hobbyist projects where cost, size, and ease of use are important factors.

Wiring and Control:

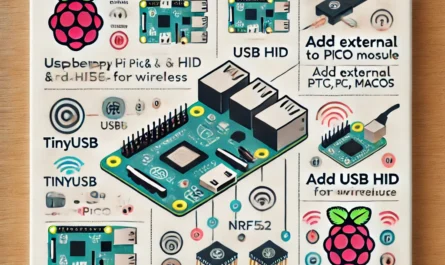

- Simple DC Operation: These motors can be driven by basic DC voltage from batteries, or controlled via a motor driver connected to a microcontroller like an Arduino to allow for more advanced functions like speed and direction control.

- Motor Driver Compatibility: Compatible with a variety of motor drivers, which can provide the necessary protection and control for direction and speed.

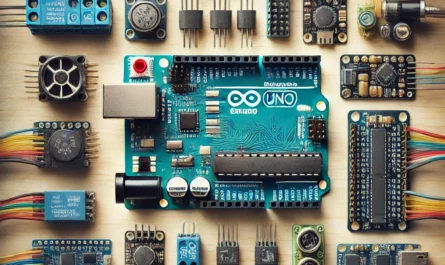

Example Setup with Arduino:

Here’s a simple example of how you can control a TT motor using an Arduino and a basic motor driver (like the L298N or L293D):

Circuit Components:

- Arduino Board

- TT Motor

- Motor Driver (e.g., L298N, L293D)

- External Power Supply (if required by the motor driver)

- Jumper wires

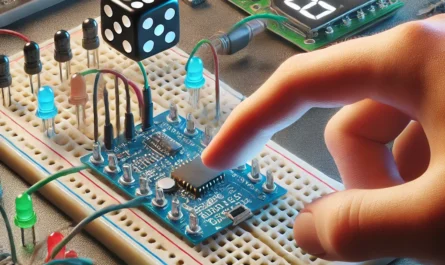

Basic Wiring Guide:

- Connect the Motor to the Motor Driver: Attach the motor terminals to the outputs on the motor driver module.

- Connect the Motor Driver to Arduino:

- Connect the input pins on the motor driver to the Arduino digital pins.

- Connect the enable pin on the motor driver to a PWM-capable pin on the Arduino if you want to control motor speed.

- Power Supply:

- Provide power to the motor driver. If using a model like the L298N, it might require a higher voltage, which should be connected to its dedicated power input.

- Ensure the ground of the Arduino is connected to the ground of the motor driver.

- Programming:

- Write a simple sketch to control the motor via the Arduino, using

digitalWrite()to set direction andanalogWrite()to control speed if using PWM.

- Write a simple sketch to control the motor via the Arduino, using

// Example Arduino Code for Controlling a TT Motor

int motorPin1 = 3; // Motor pin 1 connected to digital pin 3

int motorPin2 = 4; // Motor pin 2 connected to digital pin 4

int enablePin = 5; // PWM pin for speed control

void setup() {

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

pinMode(enablePin, OUTPUT);

}

void loop() {

digitalWrite(motorPin1, HIGH); // Set motor direction

digitalWrite(motorPin2, LOW);

analogWrite(enablePin, 128); // Set speed (0-255)

delay(1000);

digitalWrite(motorPin1, LOW); // Reverse direction

digitalWrite(motorPin2, HIGH);

delay(1000);

}

TT motors are a great choice for those starting out in robotics or for any project where size, cost, and simplicity are key considerations.