🔍 Introduction

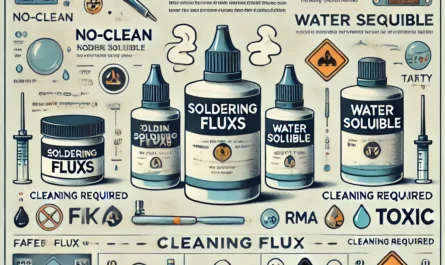

MG Chemicals 8341 is a no-clean liquid flux designed for precision soldering, rework, and assembly of both leaded and lead-free components. With a mild formula and low-residue finish, it is favored by electronics professionals and hobbyists working on delicate PCBs, SMD components, and repair projects. This review explores its features, applications, safety, and tips for best results.

📋 Key Specifications

| Parameter | Description |

|---|---|

| Type | No-Clean Liquid Flux |

| Base | Alcohol-based with rosin |

| Appearance | Transparent, light amber liquid |

| Halide Content | None (Halide-Free) |

| Flux Activity | Mild |

| Compatibility | Leaded & Lead-Free Solder |

| Cleaning Required | No (unless required by standards) |

| Shelf Life | ~2 years (in sealed container, cool storage) |

| Packaging | Available in pens, bottles, and dispensers |

⚙️ Performance and Applications

MG 8341 is known for:

- Smooth solder joint formation with strong adhesion ✅

- Minimal smoke and odor during soldering 🔇

- Excellent for surface-mount technology (SMT) and fine-pitch components 🧠

- Rework and repair of PCBs, including small-scale manufacturing 🛠️

- Suitable for wave, reflow, and hand soldering methods 🌊🔥

Its low-residue formulation ensures clean-looking boards without post-solder cleanup, making it ideal for quick repairs and prototypes.

👍 Pros and 👎 Cons

✅ Pros:

- True no-clean performance (leaves minimal, non-corrosive residue)

- Fast wetting and strong capillary action for tight components

- Safe on sensitive electronics (including multilayer PCBs)

- Dries quickly and evenly

- Halide-free, reducing risk of ionic contamination

❌ Cons:

- Not strong enough for heavily oxidized surfaces

- May require agitation before use due to alcohol content

- Flammable — use with care and ventilation

🛡️ Safety and Handling

- Use in a well-ventilated area 🌀

- Store away from open flames 🔥

- Wear protective gloves and eyewear if using frequently 🧤🕶️

- Avoid skin contact and inhalation of fumes 😷

- Dispose according to local hazardous material regulations

While classified as no-clean, cleaning may still be required in military, aerospace, automotive, or medical applications due to reliability requirements.

🧰 Ideal Users and Use Cases

- Electronics repair technicians 🔧

- Hobbyists building IoT or Arduino-based projects 📡

- Makers working with SMD and BGA components 🔍

- Lab environments and prototype fabrication 🧪

Its ease of use, reliability, and clean finish make it a go-to for day-to-day soldering where quality and efficiency matter.

🌟 Final Verdict

MG Chemicals 8341 is a solid, professional-grade no-clean flux that delivers what it promises: clean joints, smooth operation, and no mess. While it’s not a miracle worker for corroded pads, it excels in modern precision soldering, where clean and safe results are paramount.

Recommended for: Engineers, repair techs, electronics students, and anyone tired of cleaning up after their flux. 🧼⚡