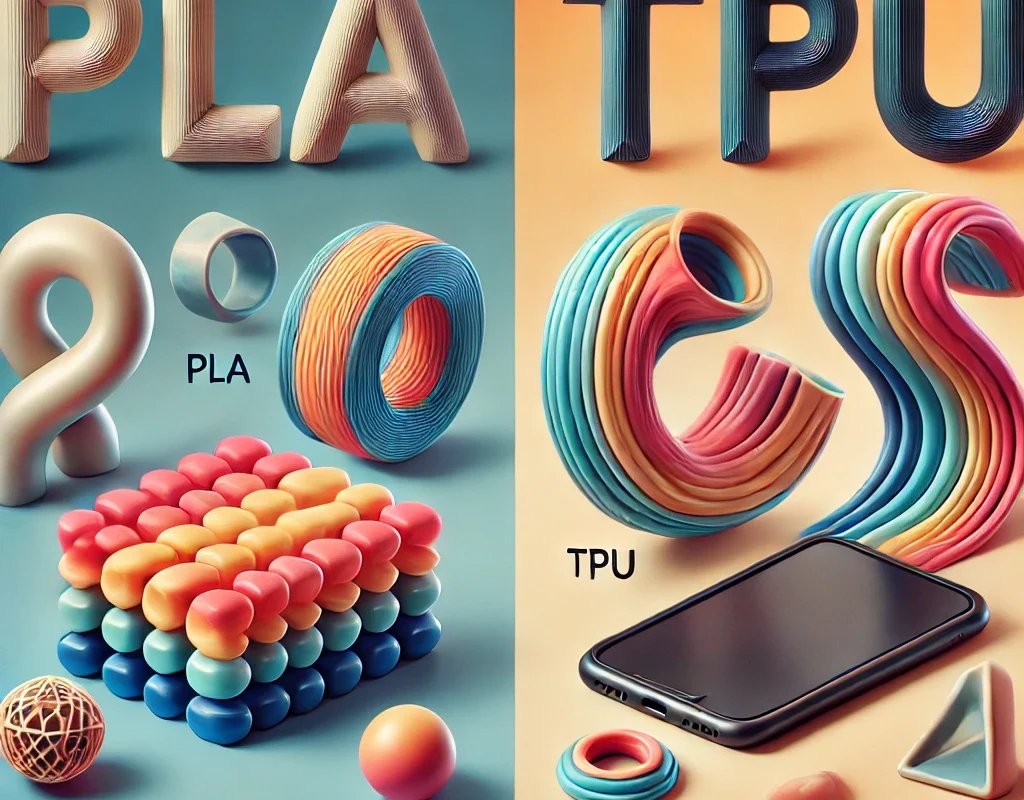

Here’s the scoop on these two superstar materials! 🎯🔧

🧊 1. PLA (Polylactic Acid)

PLA is the most popular, beginner-friendly 3D printing material!

🎯 Why PLA Rocks for Robots:

- ✅ Easy to Print: Minimal warping, stable layers, great accuracy.

- ✅ Rigid & Strong: Excellent stiffness, ideal for robot frames, supports, and chassis.

- ✅ Low Cost: Highly affordable and widely available.

- ✅ Detail-Oriented: Great for precise mechanical parts and detailed components.

📌 Best Robot Applications for PLA:

- Rigid frames and chassis

- Motor mounts & brackets

- Servo holders and gears

- Non-flexible structural components

⚠️ Limitations of PLA:

- Brittle under heavy stress or impacts.

- Limited flexibility and lower durability under high torque or repeated stress.

🛞 2. TPU (Thermoplastic Polyurethane)

TPU is a flexible filament that opens up amazing possibilities for dynamic robot parts!

🎯 Why TPU Shines for Robots:

- ✅ Excellent Flexibility & Durability: Absorbs shocks, vibrations, and impacts!

- ✅ Fantastic Grip & Traction: Perfect for wheels, tracks, grippers, and bumpers.

- ✅ High Impact Resistance: Handles drops and collisions gracefully!

- ✅ Chemical & Wear Resistant: Lasts longer under friction and rough usage.

📌 Best Robot Applications for TPU:

- Flexible wheels and tracks 🛞✨

- Robot grippers and fingers for gentle grasping 🤖👌

- Protective bumpers and padding to cushion impacts ⚡

- Flexible joints or soft robotic parts (e.g., footpads, hinges)

⚠️ Limitations of TPU:

- More challenging to print (flexible nature may cause filament jams or uneven layers without proper setup).

- Generally requires slower printing speeds and special extruder setups.

🥊✨ Head-to-Head: PLA vs TPU Comparison

| Feature | PLA 🌟 | TPU 🛞 |

|---|---|---|

| Ease of Printing | ✅ Easy | ⚠️ Moderate (slower, special setup) |

| Flexibility | ❌ Low | ✅ Very High |

| Durability | ⚠️ Moderate (brittle) | ✅ Excellent (impact-resistant) |

| Rigidity | ✅ High | ⚠️ Low (very flexible) |

| Price | ✅ Affordable | ⚠️ Slightly Higher |

| Robot Uses | Structural components, precise parts | Wheels, bumpers, flexible parts |

🚀 Best Strategy for DIY Robots: Use Both!

Combining PLA and TPU gives you the best of both worlds! 🌟🤖🖨️

🎉 Ideal Hybrid Robot Example:

- PLA chassis & rigid body frame (strength, rigidity, precision)

- TPU wheels and grippers (excellent grip, flexibility, durability)

- PLA mechanical parts (servo brackets, motor mounts)

- TPU bumpers and footpads (shock-absorbing, protecting delicate components)

This combination makes your DIY robot super robust, versatile, and capable of tackling any challenge! 🚀✨🛞

🥳 Conclusion:

- 🎯 PLA is your go-to for rigidity, precision, affordability, and easy printing.

- 🛞 TPU shines in dynamic, flexible, high-impact robot components, offering unmatched durability and grip.

Mix both materials smartly to build EPIC DIY robots! 🎉🚀✨