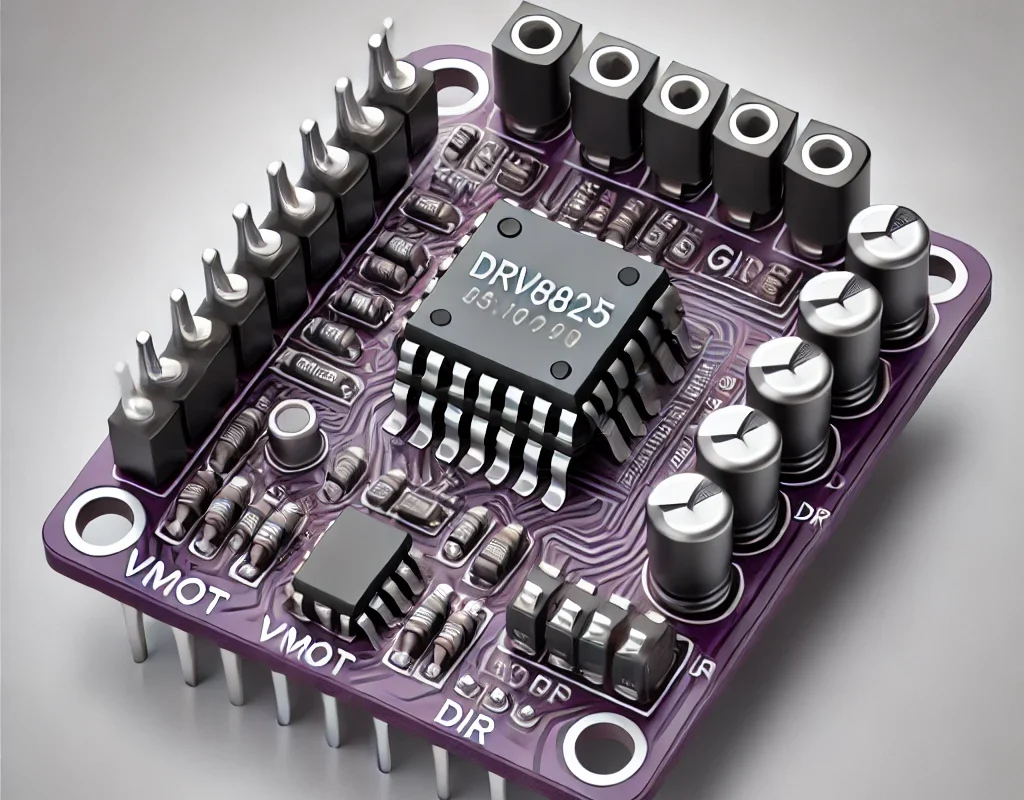

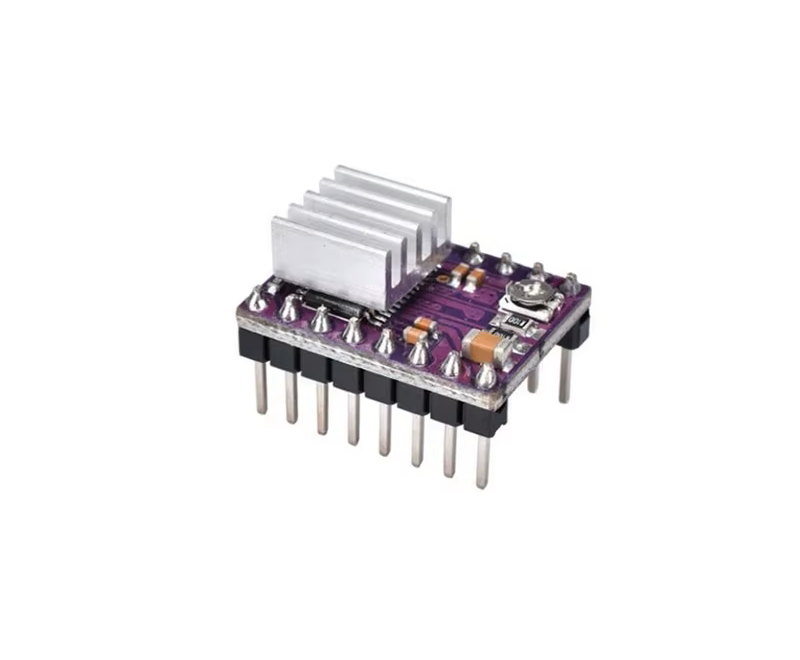

The DRV8825 is a high-power stepper motor driver module widely used in 3D printers, CNC machines, and robotics. It provides precise control over stepper motors and supports microstepping, allowing for smooth and accurate movement.

🔹 1. What is the DRV8825?

- The DRV8825 is a bipolar stepper motor driver that can drive NEMA 17 and NEMA 23 stepper motors.

- It is more powerful than the A4988, offering higher current handling and microstepping precision.

- Works with Arduino, Raspberry Pi, ESP32, and other microcontrollers.

📌 Key Features:

- Motor Voltage: 8.2V – 45V

- Logic Voltage: 3.3V / 5V (Arduino Compatible)

- Max Current: 2.5A per coil (with cooling)

- Microstepping Support: 1, 1/2, 1/4, 1/8, 1/16, 1/32 steps

- Thermal & Overcurrent Protection

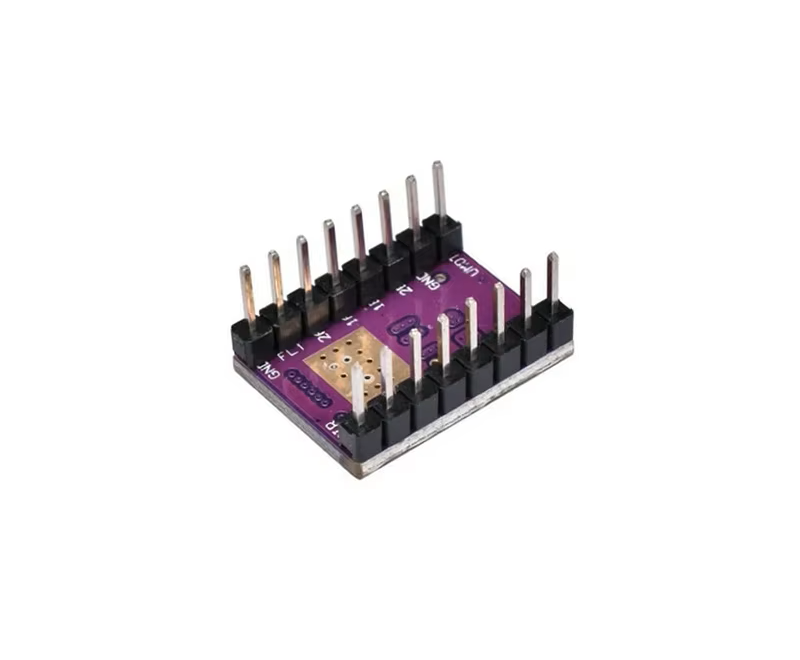

🔹 2. DRV8825 Pinout & Functions

The DRV8825 module has 16 pins for motor control and microstepping configuration.

| Pin | Function | Connection |

|---|---|---|

| VMOT | Motor Power (8.2V – 45V) | External Power Supply |

| GND | Ground | Common Ground |

| VCC | Logic Power (3.3V – 5V) | Arduino 5V |

| GND | Ground | Common Ground |

| STEP | Step Signal (Pulse Input) | Arduino Digital Pin |

| DIR | Direction Control | Arduino Digital Pin |

| EN (Enable) | Enables Driver (LOW = ON) | Arduino Digital Pin |

| MS1, MS2, MS3 | Microstepping Settings | Set to GND / VCC |

| SLEEP | Sleep Mode (LOW = Off) | Pull HIGH to Enable |

| RESET | Reset Driver | Pull HIGH to Enable |

| FAULT | Error Indicator | Not Required |

| OUT1, OUT2, OUT3, OUT4 | Motor Coil Outputs | Stepper Motor Coils |

📌 Important:

- VMOT must be connected to motor power (e.g., 12V, 24V).

- Microstepping (MS1, MS2, MS3) determines step resolution.

- STEP & DIR control motor speed and direction.

🔹 3. How DRV8825 Works

- The DRV8825 receives signals from the microcontroller to move the stepper motor one step at a time.

- Pulse on STEP pin → Moves motor one step.

- DIR pin controls direction (HIGH = Clockwise, LOW = Counterclockwise).

- Microstepping reduces vibrations and provides precise motor control.

📌 Microstepping Settings (MS1, MS2, MS3 Pins)

| MS1 | MS2 | MS3 | Microstep Mode |

|---|---|---|---|

| LOW | LOW | LOW | Full Step (1x) |

| HIGH | LOW | LOW | 1/2 Step |

| LOW | HIGH | LOW | 1/4 Step |

| HIGH | HIGH | LOW | 1/8 Step |

| LOW | LOW | HIGH | 1/16 Step |

| HIGH | LOW | HIGH | 1/32 Step |

🔹 4. Connecting DRV8825 to Arduino

🛠 Required Components

- 1x Arduino (Uno, Mega, etc.)

- 1x DRV8825 Stepper Motor Driver

- 1x NEMA 17 Stepper Motor

- 1x 12V or 24V Power Supply

- 1x 100µF Capacitor (Prevents Voltage Spikes)

- Jumper Wires

🛠 Wiring

| DRV8825 Pin | Arduino Pin / Connection |

|---|---|

| VMOT | 12V or 24V Power |

| GND | Common Ground |

| VCC | 5V (Arduino) |

| GND | GND (Arduino & Motor Supply) |

| STEP | D9 |

| DIR | D8 |

| EN | D7 (Optional, LOW to Enable) |

| MS1, MS2, MS3 | Set for Microstepping (GND/VCC) |

| OUT1, OUT2, OUT3, OUT4 | Stepper Motor Coils |

📌 Always connect a 100µF capacitor across VMOT & GND to prevent voltage spikes.

🔹 5. Arduino Code for Controlling a Stepper Motor

#define STEP_PIN 9

#define DIR_PIN 8

void setup() {

pinMode(STEP_PIN, OUTPUT);

pinMode(DIR_PIN, OUTPUT);

}

void loop() {

digitalWrite(DIR_PIN, HIGH); // Set Direction (Clockwise)

for (int i = 0; i < 200; i++) { // Move 1 full revolution (200 steps)

digitalWrite(STEP_PIN, HIGH);

delayMicroseconds(500); // Control Speed

digitalWrite(STEP_PIN, LOW);

delayMicroseconds(500);

}

delay(1000); // Pause

digitalWrite(DIR_PIN, LOW); // Change Direction (Counterclockwise)

for (int i = 0; i < 200; i++) {

digitalWrite(STEP_PIN, HIGH);

delayMicroseconds(500);

digitalWrite(STEP_PIN, LOW);

delayMicroseconds(500);

}

delay(1000);

}

📌 What happens?

- The motor rotates 1 full revolution clockwise.

- Pauses for 1 second.

- Then rotates 1 full revolution counterclockwise.

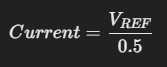

🔹 6. Adjusting DRV8825 Current Limit

To prevent motor overheating or overcurrent damage, the current limit must be set correctly.

✅ Formula for Current Limit

- VREF = Reference Voltage (Measure with Multimeter on VREF Pin)

- Max Current = 2.5A (With Heatsink)

- Set VREF between 0.5V – 1.2V

📌 To Adjust Current:

- Measure VREF using a multimeter (Touch the small potentiometer on DRV8825).

- Turn the potentiometer clockwise to increase, counterclockwise to decrease.

- For NEMA 17 stepper motors (1.5A max), set VREF to ~0.75V.

🔹 7. Applications of DRV8825

✅ 3D Printers – Controls precise motor movements.

✅ CNC Machines – Used for stepper motor control.

✅ Robotics – Drives robotic arms, wheels, and actuators.

✅ Automated Systems – Used in conveyor belts, automation.

✅ DIY Motorized Projects – Any project requiring high-precision motor control.

🔹 8. DRV8825 vs Other Stepper Drivers

| Feature | DRV8825 | A4988 | TMC2209 |

|---|---|---|---|

| Max Voltage | 45V | 35V | 29V |

| Max Current | 2.5A | 1.5A | 2.0A |

| Microstepping | 1/32 | 1/16 | 1/256 |

| Heat Dissipation | Moderate | High | Low |

| Best For | High-power steppers | Low-power motors | Silent operation |

📌 Verdict:

- DRV8825 is better than A4988 for higher power motors.

- TMC2209 is best for silent operation.

🎯 Conclusion

- The DRV8825 is a high-performance stepper motor driver with 1/32 microstepping.

- Handles up to 2.5A per coil, making it stronger than A4988.

- Used in 3D printers, CNC machines, and robotic applications.

- Supports PWM control, direction control, and current adjustment.